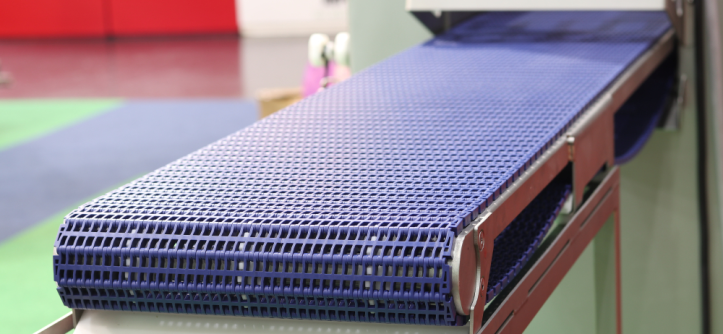

It is a sort of transport belting comprising of infusion shape modules and pivot poles built in an interlaying block example to frame a belt.

The belt is decidedly determined by sprockets drawn in with the underside of the belt. It is generally utilized in the Food Processing industry, Box, Carton and Paper industry and more for its advantages to productivity and dependability in passing on frameworks.

So, even when you wil be looking to get some belting suppliers, here is a couple of things you need to have in mind.

Origin

In 1901, Sandvik imagined and began the development of steel lines. In 1905 Richard Sutcliffe designed the main lines for use in coal mineshafts which altered the mining business. In 1913, Henry Ford presented the mechanical production systems at Ford Motor Company’s Highland Park, Michigan plant.

In 1957, the B. F. Goodrich Company protected a transport line that it proceeded to create as a Turnover. Joining a half-bend, it enjoyed the upper hand over traditional belts of a more extended life since it could uncover all its surface region to mileage.

Benefits

It is predominant in plants for its particular benefits in food and non-food applications the same. The accompanying attributes can prompt diminished personal time, brought down support costs and an in general worked on primary concern.

Solid sterilization capacity

The sterile advantages for food handling plants incorporate the non-permeable thermoplastics, to some extent uncovered pivot poles and FDA-agreeable materials.

Simple support and fix

On account of a harmed module, a basic extraction of the neighboring plastic poles will fix the belt (no compelling reason to eliminate the whole belt from the passing on framework). Likewise, insignificant instruments are required for extricating the plastic bars, which means simple fix and lower upkeep costs.

Expanded following capacity

It is pushed forward with positive drive (rather than rubbing drive) using a progression of sprockets. This kills slippage and prompts a solid following ability with the possibility to decrease vacation for following fixes.

Limited expenses through low strain frameworks

They are low pressure frameworks, which considers the utilization of less pulleys. This implies a less mind boggling framework and decreased establishment costs. The low-pressure ones additionally slice down on wear to orientation and auxiliary parts, broadening item life and bringing down upkeep costs. See more here https://blog.habasit.com/uncategorized/material-selection-when-using-a-plastic-modular-belt/

Improved on corner and turn route

At the point when a passing on framework calls for corners and turns, it effectively adapts to the situation, as it can explore around corners and turns utilizing just one belt and one engine.

Dependable and tough.

Plastic measured belting goes through no fraying or tearing. Additionally, the plastic modules can withstand cruel conditions and proposition high protection from abrasives and corrosives.

For fast substitutions to harmed belts, essentially give your series number or measured belting HS code and our day in and day out nearby administrations will return your application line to full limit.

The capacity to withstand both high hotness and freezing cold temperatures and cycles in food taking care of its frameworks. In the event that your creation line requires food-grade belting for baking and freezing, perceive how this FDA-endorsed line can take your business to new spots.

It maintains the track

They run on unadulterated positive drive. Dissimilar to the grating drives required by other engineered belts, they uses low-pressure drive frameworks.

Simple to run in close bends, they run as expected and reliably where different ones essentially can’t. A plastic measured one can go here and there slants, turn numerous corners, and return to the beginning utilizing just one engine and one belt.

As you push it quicker, you can see a striking expansion in commotion—a genuine downside in some workplaces where clamor levels should be kept to a base. In the event that you can run consistent rather than at rapid.

Inquisitive with regards to the expense and energy reserve funds that it can bring to your creation line? Converse with the line specialists at MIPR Corp. We stock and modify a full scope of particular belting and we transport tests same-day.

Adaptable material

It includes a significant capacity inside numerous creation processes, specifically when the upsides of positive drive and following are vital.

Materials are solid and impervious to scraped spot and consumption. They can be worked to practically any length and width and can be fitted with flights, sidewalls and different frill.

Modutech matches all significant brands for quality and running productivity and is seriously valued. We ensure a most extreme seven working days to conveyance.

Adaptable conveyor framework

It has the extraordinary capacity to arrange chicanes and curves when joined inside the solitary. They can be fabricated to convey a 90 degree turn or 180 degree turn framework. Click here to read more.

Conveyor line

It is normal to have three layers: a top cover, a cadaver and a base cover. The motivation behind the corpse is to give strength and shape. The body is frequently a woven or metal texture having a twist and weft.

The twist alludes to longitudinal strings which attributes of opposition and versatility characterize the running properties of the belt.

The weft addresses the entire arrangement of cross-over links permitting to the belt explicit opposition against cuts, tears and impacts and simultaneously high adaptability.

The most widely recognized corpse materials are steel, polyester, nylon, cotton and aramid. The covers are typically different elastic mixtures determined by utilization of the belt.

Steel lines are utilized when high strength class is required. This has a strength class of 10.000 N/mm and it works at Chuquicamata mine, in Chile.

Polyester, nylon and cotton are famous with low strength classes. Aramid is utilized in the reach 630 – 3500 N/mm. The upsides of utilizing aramid are energy reserve funds, upgraded lifetimes and further developed usefulness. For instance, a 2250 N/mm, 3400 m long underground belt introduced at Baodian Coal Mine, part of in Yangzhou Coal Mining Company, China, was accounted for to give energy investment funds of over 15%.

Material streaming over it might be made using a beltweigher.

The ones with routinely separated allotments, are utilized for moving free materials up steep slopes.

They are utilized in self-dumping mass tankers and in live base trucks. The innovation is likewise utilized like moving walkways or lifts, just as on many assembling mechanical production systems.

Division and Grocery stores frequently have it at the look at counter to move shopping things.

Ski slants additionally go through lines to move skiers the slope.